Introduction

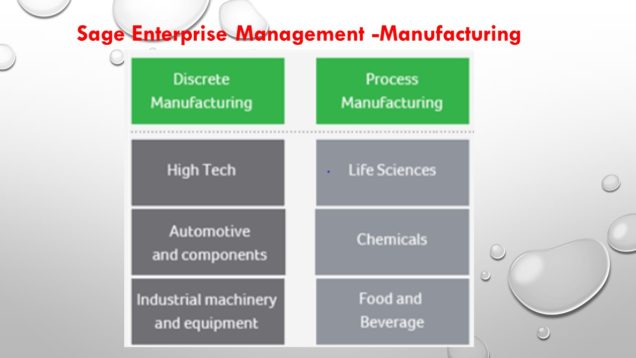

There are various erp software companies in dubai but, Sage X3 from Sage manages your entire manufacturing operation faster and more effectively – from procurement and scheduling to shop floor, inventory, sales, and financials and provides better insight on quality and costs to promote strategic collaboration and improved operational efficiency.

Comprehensive Technical Data

accounting Software companies in dubai offer many local and global accounting products for simple trading and service requirements. However, if the requirement is more comprehensive and encompasses manufacturing-related processes then Sage ERP X3 from Sage becomes an outstanding choice to consider. Sage ERP X3 provides a common repository for sharing detailed product information across sales, purchasing, inventory, and production. Various material tracking modes are supported by associating products with unique control attributes such as lot numbers, expiration dates, and QC technical sheets. Sage ERP X3 supports multilevel bills of material and usage controls for distinguishing prototypes, engineering BOMs, production BOMs, and sales kits. BOM usage is also controlled by validity dates and production quantities, which can be by unit, a lot for lot, 100- or 1,000-unit batches. Work and cost centers can be associated with machine and labor cost dimensions, resources, and factory calendars. A product can have multiple routings for manufacturing and subcontracting operations. BOMs can be associated with special routings that perform JIT material allocations when necessary. Routing operations are assigned fixed and variable setup and run times and can accommodate forward and backward scheduling. Alternate work centers and material and labour resources can be identified to handle overload situations. Technical sheets can be associated with routing operations to support manufacturing quality control.

Cost Accounting

Many accounting software companies in dubai do not offer cost accounting functionality. Sage ERP X3 supports the ability to establish an annual standard cost, perform standard cost revisions, calculate multiple simulated standard costs with user-defined parameters, and develop cost budgets for planning standard costs for future periods. Costs can be attributed to materials, machines, labor, subcontracting, and overhead. Variances can be calculated on any two costs of the same type or between two costs of different types.

Planning

Multisite MPS for medium-to-long-term planning needs includes features for performing budget analyses and feasibility simulations. It also calculates net multisite requirements, generates re-planning messages, and analyses the impact of load demands. MPS makes the best use of user-defined reordering parameters such as fixed period coverage, seasonality patterns, and net reorder quantities. The planning horizon is user-defined with allowances for up to five years. Sage ERP X3 supports finite and infinite capacity requirements planning. Finite capacity planning can be done automatically by using a powerful, integrated optimization facility that helps resolve bottleneck areas according to user-defined constraints. Sage ERP X3 provides an ideal tool for planners to compare loads on work centers imposed by existing and proposed work orders, taking into consideration the associated capacity of each work center and work order due dates. MRP schedules for products at single or multiple sites can then be generated. Most accounting software companies in dubai do not provide MPS/ MRP planning

Work Order Release

Sage ERP X3 provides flexible work order release management capabilities, allowing multiple items per production order and real-time material, machine, and labor allocations with reason codes. Work in process tracking, production status reporting, and a breakdown of actual production costs by shop traveler are also provided. Sage ERP X3 supports the ability to do rate-based scheduling with backflushing.

Decision-Making Tools

Sage ERP X3 provides material planners with an array of screens and reports in the quantified form of pie charts, bar charts, and graphs to assist in making meaningful material and capacity decisions. Included are multisite MPS charts for product families, MRP schedules for products at single or multiple sites, bottleneck work center charts, and a planner’s workbench. Time-phased pegging ties requirements back to original demand sources. Sage ERP X3 calculates a variety of performance indicators including material, operation and production yield, capacity, and resource utilization rates.

Conclusion

Sage ERP X3 offers a choice of production management methods—by the job, order, or inventory. Technical data can be defined by price lists, cost centers, and stations as well as a production process sheet management function.

With Sage we count a user once and only once. Once logged in he has access to any or all the companies based on the security profile – the concurrent user license consumed is still one. He may access the license from multiple devices – the count is still one and the latest login is the active one. Time out rules can be defined for forcing logouts if users forget to do so. Mobile access does not burden you with additional licensing costs. Indirect access – say through a CRM is enabled through a dedicated link and does not consume a user count on the Sage X3 ERP. Many products like microsoft dynamics 365 or Orion use named user licensing and increase the licensing counts on account of such reasons.

Sage is one of the leading erp software company in dubai that offers premium manufacturing capability with its flagship product Sage ERPS X3 a management control function with the calculation of forecast and actual costs, a finite capacity production scheduling function, a planning function incorporating a production coordination program, calculation of net requirements, and an overall production management function. Various performance indicators are available, ensuring optimum industrial production quality and traceability.